Company Profile

Established with an advanced concept

Established in 1996, Maxmill Machinery Co., Ltd. specializes in the design and manufacture of vertical machining centers. Since the company was established, the concept behind Maxmill has been providing the best machinery available for achieving the highest levels of productivity, accuracy and quality. Forward thinking and constant new idea applications have established Maxmill as a highly reputed manufacturer in vertical machining centers. Each Maxmill vertical machining center is a highly dependable machine, manufactured with the Maxmill tradition of outstanding design - assuring high quality machining and minimum trouble year after year. In addition to the excellent design and manufacturing capabilities, Maxmill utilizes the most rigorous quality control systems at each step throughout the entire manufacturing process. What we do is to ensure each Maxmill VMC will be fully satisfied to each domestic and international customer.

Brilliant research and development capabilities

Our commitment to all of our customers drives us to constantly research new technologies to upgrade Maxmill machines. Outstanding research and development is a key factor in this process. At Maxmill, we have highly qualified R&D engineers with over 10 years' experience in the machine tool industry. The design procedures are done by using advanced software system for simulation on computer. One reason for the excellence of Maxmill VMC's results from our innovative design concepts. We will maintain this tradition to stay competitive now and in the future.

Quality assurance

Quality is the cornerstone of Maxmill manufacturing and, as such, rigorous quality control is conducted throughout each step of the entire manufacturing process. Rigorous machine inspections are also performed in operational performance, accuracy and quality to achieve the highest standards. Sophisticated inspection instruments, such as a ball bar tester and laser instruments are applied for inspecting the machines. The quality of Maxmill machines are verified by international quality assurance systems, including: ISO 9001, JIS, DIN, UL, CSA and CE. Our efforts in quality insistence have enabled us to earn total customer trust and loyalty.

Maxmill commits itself to its customers Carrying on with continuing growth - which brings more products and better services, and to becoming a world-class, market-oriented Machining Center Manufacturer.

Quality VMC's Make a Difference.

Maxmill Machines Help You Stay Competitive.

How was this accomplished?

History

- 1960

- Established Sing Lung Trading Co., Ltd., Co-operation with Japanese Mitsutoyo, Sumitomo and Shinko as representation office in Taiwan.

- 1988

- Established Lien Sheng Mechanical and Electrical Co., Ltd., which manufactured EDM and wire cutting machines.

- 1996

- Established Maxmill Machinery Co., Ltd. Based on a background of technical experience, Maxmill has built a comprehensive vertical machining center series through researching, designing, manufacturing, assembling and final testing inspections conducted by their dedicated team of employees. Also, we have concentrated exclusively on vertical machining centers and boldly realize visionary ideas.

- 2003

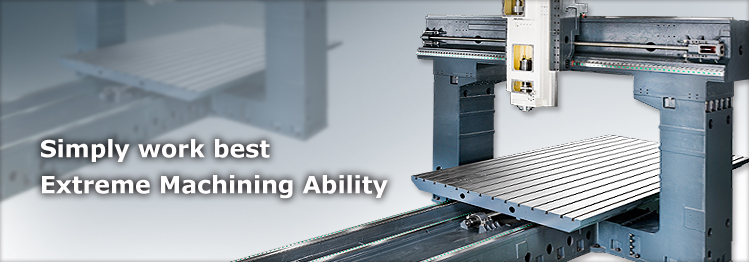

- The professional, bridge-type machining center team workers joined the Maxmill family.

- 2004

- In order to provide product variety and comprehensive services to customers, Maxmill has their whole series of CNC vertical machining centers exclusively supplied. Maxmill and dealers around the world became partners strategically for mutual benefits to penetrate into various markets. We will continuously and flexibly cooperate to bring outstanding machines and services to customers. Meanwhile, another new category that Maxmill is going to present is the double column machining center. Once again, we successfully and efficiently submitted significant products to satisfy overall customer needs.

- 2004

- With the latest technology, developed a production line of milling machines that stands out for their accuracy, quality and productivity - all at a competitive price.

- 2008

- Double column machining center upgraded to 5 faces machining center to meet the comprehensive machining requirement. Also with head storage device to provide a mighty function for machining.

- 2012

- High rigidity machining center HQM-1260 was announced.

- 2014

- The 2nd generation QMC-600 liner guideway makes a debut which developing with the idea of “Evolutionary Performance.” New model HQM-1480 & 1680 was announced. New generation of box guideway NVM-1166 was announced.

- 2016

- The introduction of the QMC-500 high-specification model enables micro drilling with high efficiency and rapid cutting.